Page 44 - Centerdrill Produktkatalog 2020 English

P. 44

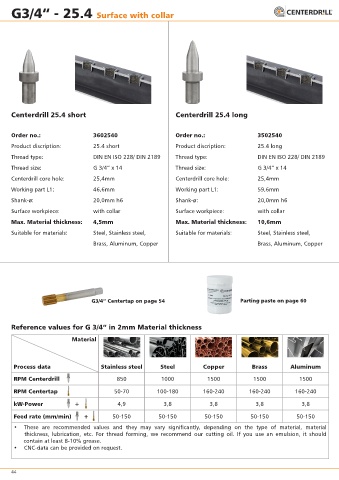

G3/4“ - 25.4 Surface with collar

Centerdrill 25.4 short Centerdrill 25.4 long

Order no.: 3602540 Order no.: 3502540

Product discription: 25.4 short Product discription: 25.4 long

Thread type: DIN EN ISO 228/ DIN 2189 Thread type: DIN EN ISO 228/ DIN 2189

Thread size: G 3/4“ x 14 Thread size: G 3/4“ x 14

Centerdrill core hole: 25,4mm Centerdrill core hole: 25,4mm

Working part L1: 46,6mm Working part L1: 59,6mm

Shank-ø: 20,0mm h6 Shank-ø: 20,0mm h6

Surface workpiece: with collar Surface workpiece: with collar

Max. Material thickness: 4,5mm Max. Material thickness: 10,6mm

Suitable for materials: Steel, Stainless steel, Suitable for materials: Steel, Stainless steel,

Brass, Aluminum, Copper Brass, Aluminum, Copper

G3/4“ Centertap on page 54 Parting paste on page 60

Reference values for G 3/4“ in 2mm Material thickness

Material

Process data Stainless steel Steel Copper Brass Aluminum

RPM Centerdrill 850 1000 1500 1500 1500

RPM Centertap 50-70 100-180 160-240 160-240 160-240

kW-Power + 4,9 3,8 3,8 3,8 3,8

Feed rate (mm/min) + 50-150 50-150 50-150 50-150 50-150

• These are recommended values and they may vary significantly, depending on the type of material, material

thickness, lubrication, etc. For thread forming, we recommend our cutting oil. If you use an emulsion, it should

contain at least 8-10% grease.

• CNC-data can be provided on request.

44